Why is the thread breaking on an embroidery machine?

This site contains affiliate links to products. We may receive a commission for purchases made through these links.

Having the thread break over and over again on your embroidery machine can be a maddening experience. It can make a 5 minute project turn into a 45 minute ordeal due to the constant rethreading of the machine again and again. In the past, when this would happen to me, I would usually give up, walk away from the machine, and hope that the situation would magically resolve itself. Now that I’ve gotten more experience, I’ve learned that there are many factors which can contribute to thread breaking on an embroidery machine.

Don’t mess with the tension

It can be tempting to start adjusting the tension on your embroidery machine, however, tension isn’t usually the culprit. Resist the urge to change the tension from its factory setting and start by checking out some of the more likely problems.

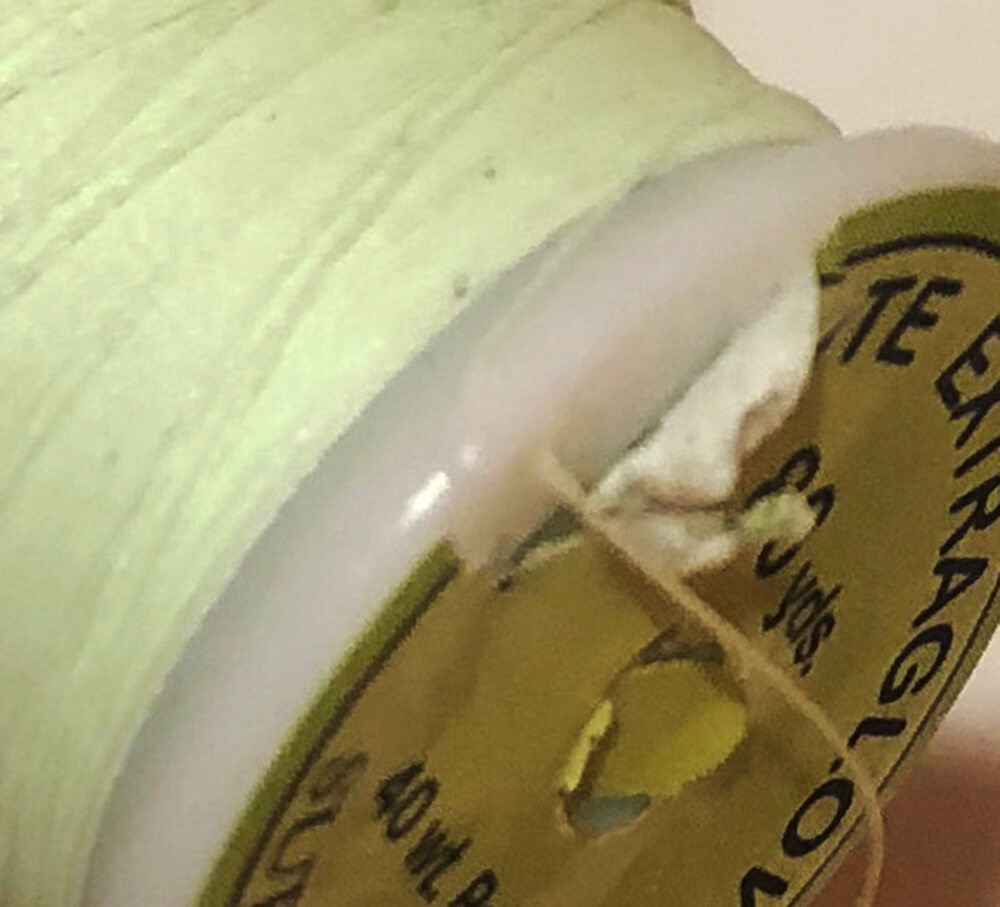

Check that little notch on the spool of thread

You know how the spool of thread has a little notch where the end of the thread is stuck? It is there to keep the thread from unwinding. But it can also wreck havoc on your stitching. As you are embroidering, the thread can get stuck in the notch which can easily cause your thread to break.

Need a solution? File down that notch to make it a nice, smooth little valley and the thread can no longer get caught on it.

Remove the spool cap

The spool cap can wreck havoc to your embroidery. The thread can easily get caught on it and break. Instead…

Use a thread stand or a cup

I first purchase a thread stand after I purchased very large spools of embroidery thread. I realized that these spools didn’t unwind nicely when placed on the spool holder on the back of my embroidery machine. It simply required too much force to unwind the thread from these large spool and my thread kept breaking.

After a little experimentation, I discovered that I had much better results if I put the big spools away from my machine and then held the thread up in the air as it was feeding into my machine. Then my arm got very tired. Fortunately I learned about thread stands and my problem was solved. In fact, it works so well that I put all my spools of embroidery thread on a thread stand, regardless of their size.

A thread stand allows the thread to gently come off the spool and unwind before making its way into the embroidery machine. There is no extra tension required to unwind the thread from the spool.

Some people swear by keeping their spools of thread in a cup by their embroidery machine. They say that it allows the thread to easily unwind. Sounds to me like a mess. I’ll stick with a thread stand.

Is the machine threaded properly?

One of the reasons why the thread might break on your embroidery machine is if the machine is not threaded properly. You may just solve your problem if you pull your thread out and completely rethread your machine.

Also, you should always thread your embroidery machine with the presser foot raised. If the presser foot is down when you thread the machine, you could end up with breakage.

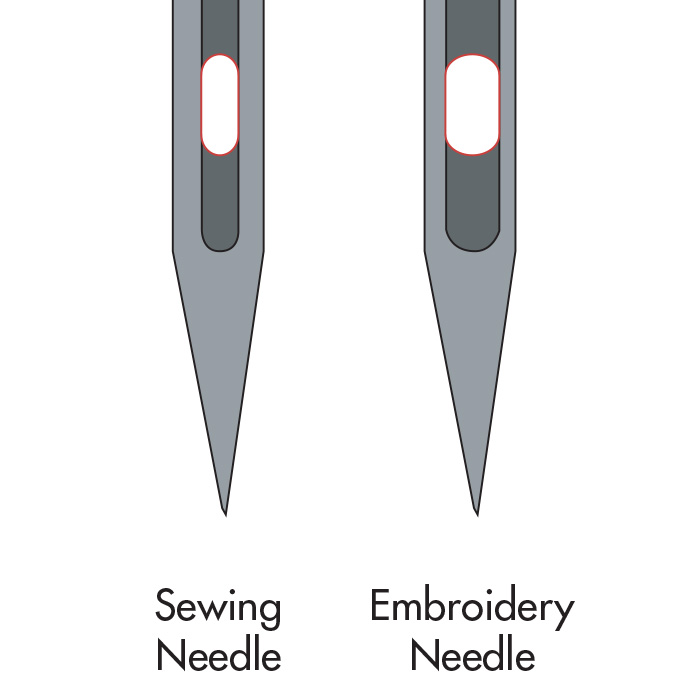

Check your needle

The type and condition of the needle you are using could be the reason why thread is breaking on your embroidery machine. First, of all, are you sure you are actually using an embroidery machine needle and not a sewing machine needle? There is a difference. Needles for machine embroidery have a larger eye which allows the thread to pass through more smoothly. Thread passing through the smaller eye within a sewing needle can easily get snagged and break.

You should also check the condition of your needle. Needles can easily get bent if they run into a hard or stiff surface. Then, in future projects, the thread can easily break. Also, if the needle is too old and worn out, it can also shred the thread. I’ve personally had thread breaking trouble when my needles get too gunked up after stitching through sticky materials.

Check your thread weight

Embroidery machines prefer a specific thread weight. For example, the Brother PE800 requires 90wt embroidery thread. Check in your manual to see what this weight is. If you are using the wrong weight embroidery thread, it could be causing your thread to break.

Check your thread age

Thread can get old and brittle. If your embroidery thread has been around for a while, it might be time to get rid of it, especially if it keeps snapping repeatedly. But I would check all of the other factors before I threw away my thread.

Check your thread brand

I’m an equal opportunity embroidery thread girl. I’ve never found one brand of machine embroidery thread to be better than others. Although, I have found some novelty types of thread (such as metallics and glow-in-the-dark) to be a bit more challenging to work with than standard machine embroidery thread. but I know there are many others out there with very strong opinions about the brand of machine embroidery thread.

Try changing the brand of thread and you may reduce the amount of thread breakage you are having on your embroidery machine.

Check your thread path

A piece of thread inside of your tension discs can cause friction against the thread moving through the machine and cause it to snap. To see if this is your problem, pull everything out, and clean the path with unwaxed dental floss or fishing line.

Check your bobbin case

A broken needle could have damaged the bobbin case. If you take it out and look at the hook part, it might show a tiny nick. Nicks and burrs on the bobbin case cause thread to break as it passes around the bobbin.

Check your needle plate

Run your finger over the foot and needle plate. It can get dinged from needles breaking or encountering an unexpected pin. Even a small burr will catch your thread and break it.

So what did I miss?

Have you found any other reasons why your thread was breaking on your embroidery machine? How did you solve it? Comment below!

Happy happy stitching!

xo

Julie

Want to remember this? Save “Why is the thread breaking on an embroidery machine?” on your favorite Pinterest board

Another tip I heard, when your thread breaks or you have any interruption in your embroidering, also take out the bobbin thread and put it back just as if it is a new bobbin. This resets the thread in the correct position to start again. This helped me and I hope it helps someone else

Does using a spray adhesive such as 505 gunk up a needle?

It can. It can gunk up just about everything.

I have a Brother VR and I have the problem that the thread is being cutted too short, every time it is cut. So the next step he makes, he can’t take the bobbinthread, because it is too short and the machine stops EVERY TIME there is a cut! So terrible! The dealer does not know what to do and I am going crazy! Do you know the solution please???

Oh no! I wish I knew. Maybe someone here will make a suggestion. Have you tried the Brother Embroidery Machine Facebook group?

Try to pull out some of the top thread before cuuting it with the thread cutter. It works for me.