What stabilizer to use for machine embroidery

This site contains affiliate links to products. We may receive a commission for purchases made through these links.

Machine embroidery stabilizer can be a bit of an enigma when you are new to the craft . There are so many varieties, it’s hard to sort out exactly what stabilizer to use for machine embroidery.

Fortunately, if you are just getting started, there are just a few different types of stabilizer you really need that will allow you to execute a wide variety of projects.

What, exactly is stabilizer for machine embroidery?

Stabilizer is a synthetic material that provides extra support for your fabric on which you are embroidering. It comes in different weights. Typically, you use heavier weight stabilizer on heavier weighted fabrics.

Some stabilizer is intended to remain on the finished product (cut away).

Other stabilizer (tear away) is temporary. You remove it (as much as possible) from the finished project.

There are also varieties of stabilizer that are water soluble. So after your finish stitching out your embroidery design, you just get the stabilizer wet, and it disappears!

Why is stabilizer needed for machine embroidery?

According to Deborah Jones in Machine Embroidery on Difficult Fabrics, The purpose of stabilizer is to “provide the foundation for the embroidery stitch.” And – you never want to embroider without it.

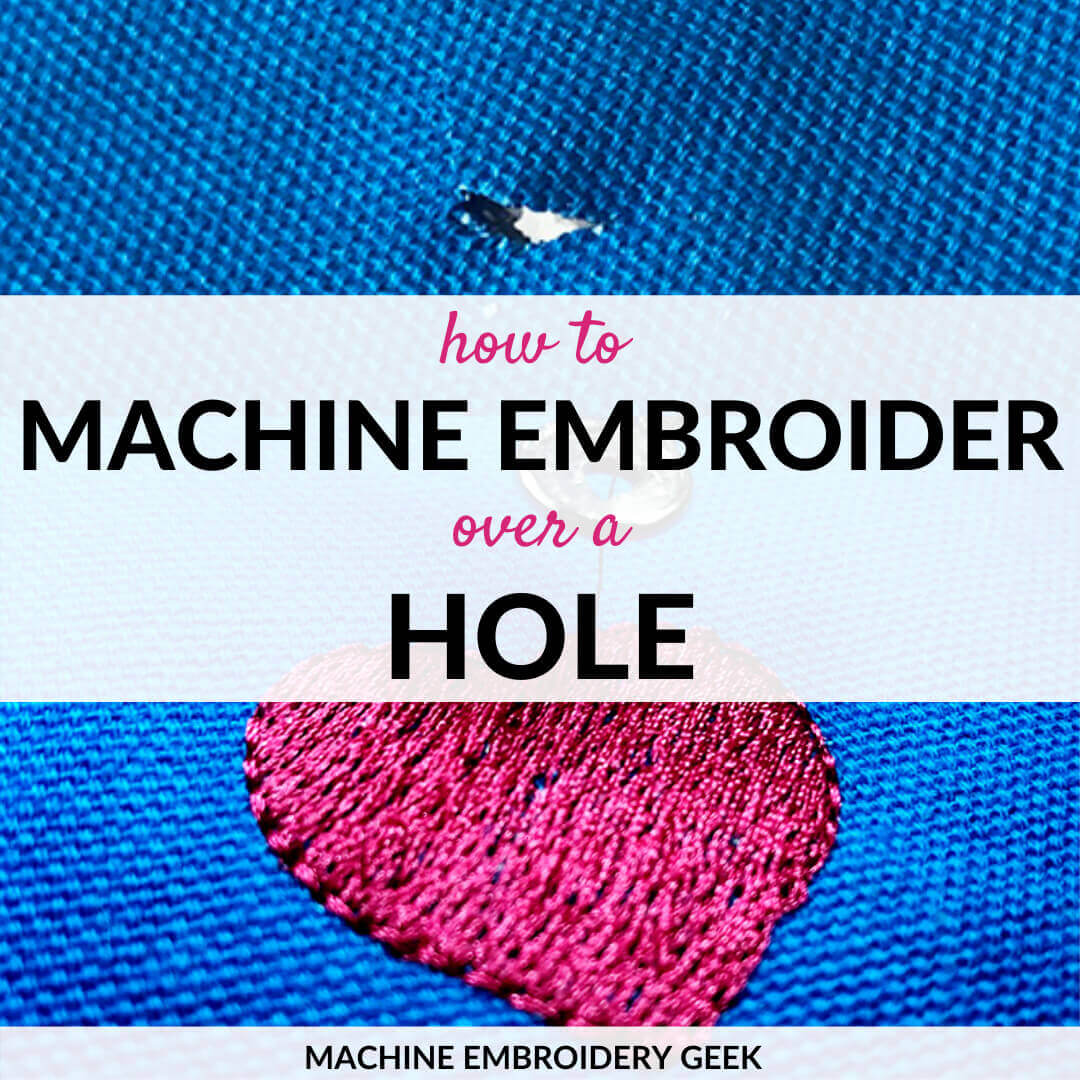

Machine embroidery puts a lot of stress on fabric. Many embroidery designs are comprised of thousands of stitches, which means A LOT of holes are being punched into the fabric. Without any stabilizer, the fabric might not hold up to all this abuse.

Fabric also has a tendency to stretch and bunch up when you are embroidering on it. But, when you adhere the fabric to stabilizer, you reduce the amount of bunching and puckering.

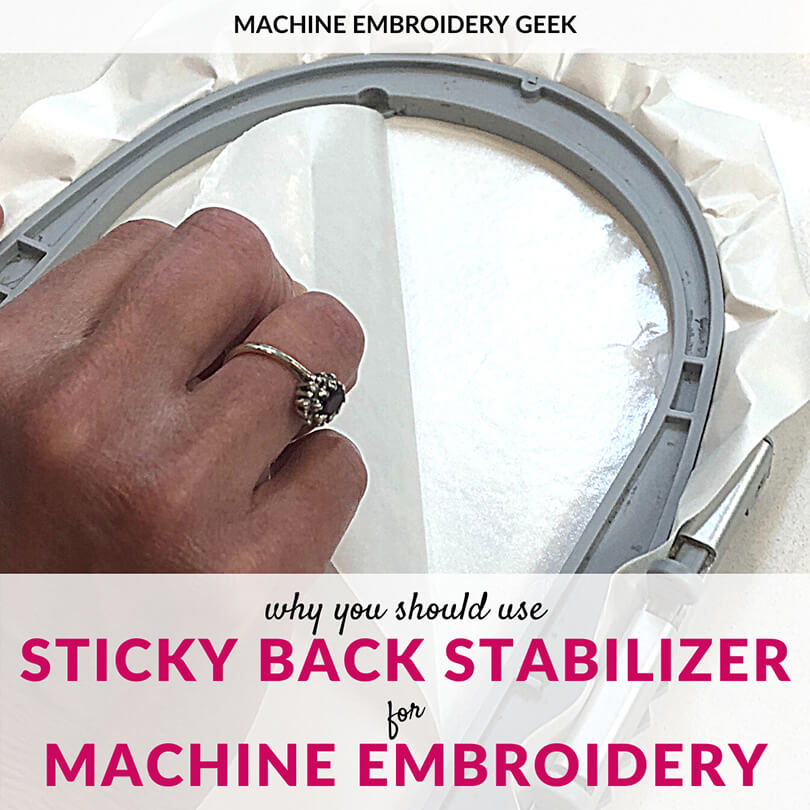

Stabilizer can also make your embroidery process easier, especially if you are working with material or a garment that is difficult to hoop.

Instead of hooping the item you are embroidering, you can hoop the stabilizer. Then, you stick your garment onto the stabilizer to hold it in place while you embroider.

This technique is called “floating”, and you can see how I float a t-shirt on a piece of hooped sticky back tear away stabilizer in this previous post.

Do you have to use stabilizer when embroidering?

Well, no, you don’t have to. But your resulting embroidery will likely be puckered, especially if you are trying to embroider on stretchy or thin fabrics.

You may be able to embroider without stabilizer if you are embroidering on very stiff fabric. But, I would not recommend it.

What is the most common stabilizer needed for machine embroidery?

If you are new to machine embroidery, it can be a bit overwhelming wrapping your head around all the different types of stabilizer. But, fortunately, you only really need a few different types. The following types of stabilizer are the most essential ones for machine embroidery

- Tear away stabilizer

- Cut away stabilizer

- Fusible poly mesh stabilizer

- Water soluble stabilizer

- Water soluble topper

- Cloud Cover

Tear away stabilizer for machine embroidery

Tear away stabilizer is literally stabilizer that you tear away from the embroidered area. After you finish stitching, you tear it and throw it away.

It is used on many different type of fabrics. As a general rule, if the item you are embroidering is not going to be worn, you can often get away with tear away as your only stabilizer.

When to use tear away stabilizer

In general, if you are embroidering on fairly durable fabrics, you can get away with just using tear away stabilizer. For example, if you are embroidering a name on a durable canvas, like a tote bag, a tear away will suffice.

Embroidery on towels is another instance where a tear away stabilizer is perfectly suitable on its own.

For most items of clothing, however, a tear away stabilizer does not offer enough support. These items should be stabilized with a cut away stabilizer instead (or used in conjunction with the tear away).

How to use tear away stabilizer

You can use tear away stabilizer in one of two ways. You can secure the tear away stabilizer in the hoop on your embroidery machine (hooping) or you can hoop the stabilizer and stick the garment to the stabilizer (floating).

Where and how to buy tear away stabilizer

You can purchase standard tear away stabilizer in a big roll and almost any embroidery supplier, and it’s fairly inexpensive. However, you will likely want to use the tear away with a temporary adhesive spray to secure your fabric or garment to the stabilizer.

There are some specialty types of tear away stabilizers that offer some distinct advantages over standard tear away stabilizer. You see, when you use standard tear away stabilizer, you will likely want to stick your fabric or garment to the stabilizer using temporary adhesive.

However, relying on temporary adhesive to stick your fabric or garment to the stabilizer can leave a sticky mess. Your embroidery hoop will get gunky, and require frequent cleanings. Sticky back and iron on tear away help you avoid the gunky mess. My personal preference is to use sticky back stabilizer.

Iron on tear away stabilizer

Iron on tear away stabilizer is pretty self-explanatory. You iron the stabilizer onto the garment, then hoop the garment and stabilizer and start embroidering. When you are done, tear away the excess stabilizer. Because you are adhering the garment to the stabilizer via the iron, you avoid having to use temporary adhesive spray.

Adhesive backed tear away stabilizer

Sticky back tear away stabilizer is my preferred form of stabilizer for two reasons. One, I avoid using temporary adhesive spray. And, two, I can float my fabric or garment in the hoop. On most of my embroidery projects, I simply hoop a piece of sticky back tear away stabilizer (shiny side up), then score around the inside edge of the embroidery hoop with a pin. Finally, I peel away the paper to expose the sticky surface. Once the sticky surface is exposed, I “float” the fabric or garment on the tear away and embroider away! Learn more about sticky back tear away stabilizer.

Cut away stabilizer for machine embroidery

Cut away stabilizer is stabilizer that stays with the garment. Have you ever noticed the wrong side of an embroidered fleece or polo with stabilizer left in place?

This is intentional. It keeps the embroidered design from becoming distorted from wash and wear.

Cut away stabilizer is almost always used on wearables. A common rule of thumb is that “if you wear it, don’t tear it, ” meaning cut away stabilizer should almost aways be used when embroidering on something that you will wear.

How to use cut away stabilizer

If I deem cut away stabilizer necessary, I usually cut a piece larger than my embroidery design and adhere it to the wrong side of my garment with temporary adhesive spray, centering it over the intended embroidered area. Then I float the garment with the cut away stuck to it on a piece of sticky back tear away stabilizer. Once I’m done stitching out the design, I remove the tear away and trim the excess cut away stabilizer away from the design.

Fusible poly mesh cut away stabilizer

Fusible poly mesh is a flexible, iron-on stabilizer that is intended to stay in the garment. It differs from standard cut away stabilizer because it is not as stiff, and it irons on. I really only use fusible poly mesh stabilizer when I’m embroidering on very stretchy knits like baby onesies and swimsuits, otherwise I just rely on standard cut away stabilizer.

Because it is a cut away stabilizer, it stays in the garment, and you can trim the excess stabilizer away after you are done embroidering on the garment.

Water soluble stabilizer for machine embroidery

Water soluble stabilizer is essential for certain types of projects. As indicated in its name, water soluble stabilizer is stabilizer that dissolves in water.

How to use water soluble stabilizer

You can either float the water soluble stabilizer with the project, or hoop the water soluble stabilizer and float the project on top.

When to use water soluble stabilizer

I, personally, use water soluble stabilizer any time I make a patch on my embroidery machine. The water soluble stabilizer provides a foundation on which you stitch out the patch. After you do a nice satin stitch around the outside edge of the patch, you simply wash away the stabilizer and you have a nice, clean finish.

Water soluble stabilizer is also essential for most free standing lace projects. This is because you need a foundation on which to stitch out the free standing lace. After you finish and rinse project, the stabilizer will disappear and you are left with lace.

Water soluble stabilizer is also used frequently for in-the hoop projects. For example, if the project has a finished satin stitch edge, you would want to use a water soluble stabilizer so that no stabilizer shows are around the outside edge.

When water soluble stabilizer is used in this manner (a foundation for embroidery), it is referred to as “mesh” water soluble stabilizer.

Mesh water soluble stabilizer is different from water soluble topper. The stabilizer is more of a fibrous material and the topper is a clear film.

Water soluble topper for machine embroidery

A water soluble topper is not necessarily a stabilizer, it’s really just a thin film that improves the coverage of your embroidery stitches.

It makes a huge difference when you are embroidering on terry cloth towels.

You simply lay a piece of the water soluble topper over the area on which you are embroidering. Then you start stitching.

The water soluble topper keeps the towel fibers from popping through your stitches and you get a nice, finished look.

Embroidery backing for baby clothes – Cloud Cover

Cloud Cover is another product that isn’t necessarily a stabilizer but a nonetheless useful and great to have on hand. It is a thin, soft, flexible and fusible material that you fuse over the wrong side of the finished embroidery or appliqué. It keeps harsh surfaces of the embroidered area on wearables from rubbing against the skin.

How to use Cloud Cover

I always fuse a piece of Cloud Cover over the back side of embroidery and appliqué on a baby onesie. In a pinch, I’ve used it as a substitute for fusible poly mesh stabilizer.

Machine embroidery stabilizer guide

|

Tear away stabilizer |

Use as the primary (and only stabilizer) for heavyweight fabrics like duffel bags or tote bags. You can also use this as a base layer for any project suitable for floating. |

| Cut away stabilizer | Use cut away stabilizer behind embroidery on clothing. As it tends to be a bit stiff, it works best on smaller embroidered areas on polos ore fleeces. Cut away stabilizer stays with the garment. |

| Fusible poly mesh stabilizer | Fusible poly mesh is a more flexible cut away stabilizer that should be used on knits. |

| Water soluble mesh stabilizer | Use on in-the-hoop projects, free standing lace or patches. |

| Water soluble topper | A water soluble topper is an essential top layer when embroidering on towels or other nappy fabrics. |

| Cloud cover | Cloud cover is a flexible, lightweight fusible material designed to be fused to the back of an embroidery design. It is most often used on the inside of baby clothes so that the back of an embroidery design will not scratch a baby’s sensitive skin. |

What are machine embroidery stabilizer alternatives?

Not convinced you need machine embroidery stabilizer? Don’t want to invest? Or, maybe it’s midnight, you need to finish a project, but you have to stabilizer on hand. If this is the case, you may be wondering if there are any machine embroidery stabilizer alternatives.

The answer is yes. I’ve heard of people using everything from coffee filters to paper towels, to even tulle to stabilize their embroidery projects. If you are in a bind, it may be worth a try, but I prefer to keep all my standard stabilizers on hand.

Frequently asked questions regarding machine embroidery stabilizer

What is the best stabilizer for machine embroidery?

The best stabilizer for machine embroidery depends on the project you are working on. If you are working with a heavyweight fabric, like a tote bag, then you will want to use a tear away stabilizer. If you are working with a knit fabric, then you will want to use a fusible poly mesh stabilizer.

Do I always need stabilizer for machine embroidery?

In most cases, yes. Stabilizer provides support for your fabric and helps to keep your stitches from becoming distorted.

What is the difference between stabilizer and topping?

Topping is a water soluble film that is placed over the area you are embroidering. It dissolves in water and helps to keep your stitches from becoming distorted.

How do I remove stabilizer from my embroidery?

If you are using a tear away stabilizer, then you can simply tear it away from your embroidery. If you are using a water soluble stabilizer, then you will need to soak your embroidery in water until the stabilizer dissolves. If you are using a cut away stabilizer, then you will need to trim away the excess stabilizer from around your embroidery.

What is the best way to store stabilizer?

The best way to store stabilizer is in a cool, dry place. You may also want to keep it in a plastic bag or container to prevent it from becoming dusty.

Do I need different stabilizer for different fabrics?

Yes. You will want to use a heavier stabilizer, like a tear away or cut away, for heavyweight fabrics. You will also want to use a fusible poly mesh stabilizer for knit fabrics.

What is the difference between cut away and tear away stabilizer?

Cut away stabilizer is a heavier stabilizer that is meant to be left in the garment. Tear away stabilizer is a lighter stabilizer that can be torn away from the garment after embroidering.

Is there a difference between fusible and non-fusible stabilizer?

Yes. Fusible stabilizer has a heat activated adhesive on one side. Non-fusible stabilizer does not have an adhesive and must be held in place with temporary spray adhesive.

What is the difference between water soluble and fusible poly mesh stabilizer?

Water soluble stabilizer dissolves in water and is best used for delicate fabrics. Fusible poly mesh stabilizer has a heat activated adhesive on one side and is best used for knit fabrics.

How can I save money on stabilizer?

Funny you should ask – that’s an entire subject for another post. Check out these clever ways to save money on machine embroidery stabilizer. If you embroider as much as I do – you’ll definitely want to know these tricks.

Well – I hope you have found this article about machine embroidery stabilizers to be helpful. If you have any other questions about machine embroidery stabilizers, please leave your questions in the comments below.

Good luck & Happy stitching

xo

Julie

[…] embroidering a curved neckline, it’s crucial to use the appropriate stabilizer to ensure the best results. The stabilizer provides support to the fabric during the embroidery […]